Recovery of organic waste for the production of biogas

Hybrid Biogas Machine

Generate fuel gas in remote areas

As part of the Metanogenia objective, a small-scale biogas plant powered by photovoltaic energy, a Hybrid Biogas Machine (HBM) has been designed and built. This plant is designed to be built with cheap materials and anywhere in the world, to generate fuel gas in remote areas and thus help other economic development processes.

The main novelty of this technology is that it increases the production of thermal energy compared to conventional techniques in any remote place and this allows food processing activities to be carried out.

Designed to operate in remote areas of Africa

HBM

Technical description

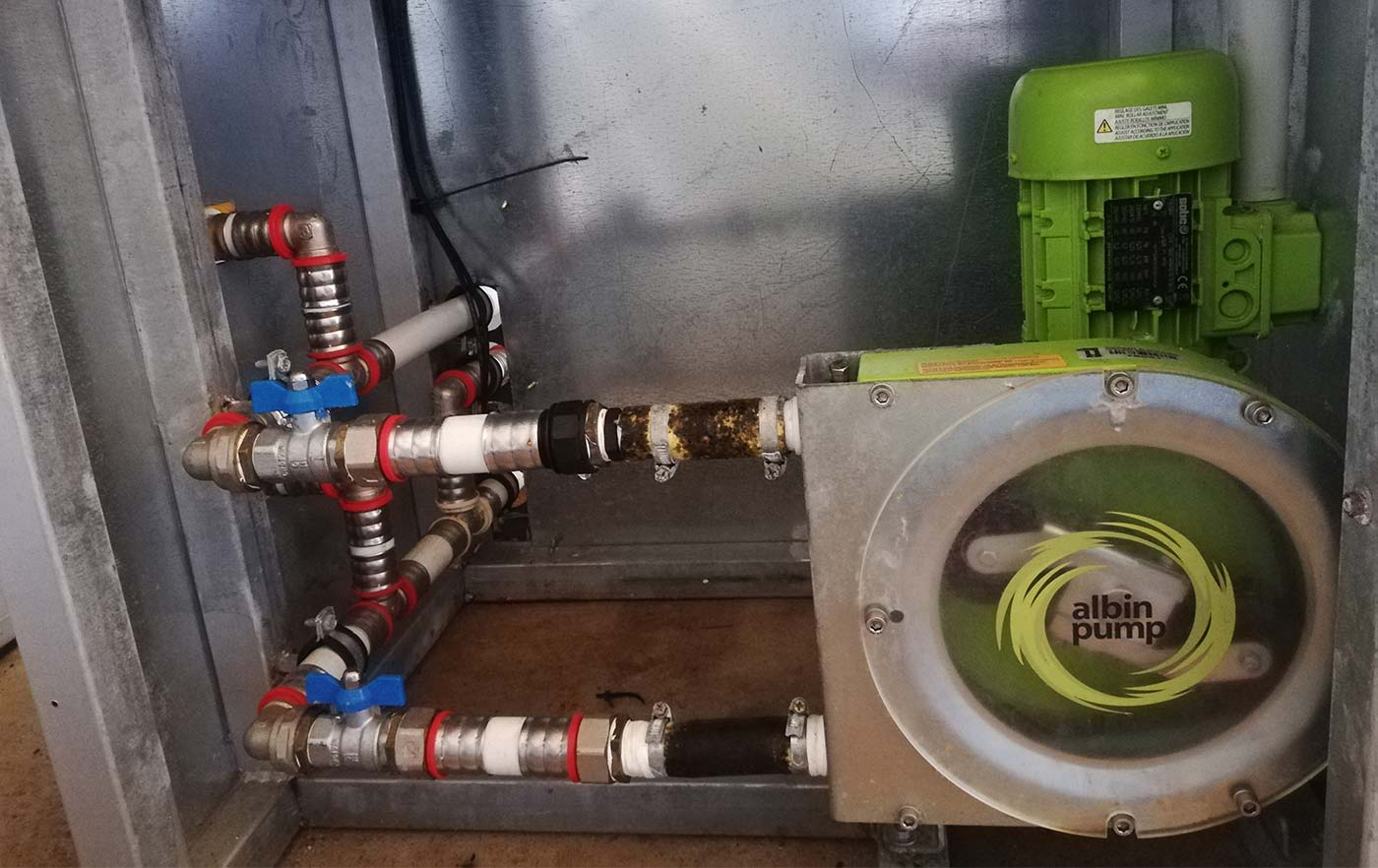

The HBM is a scalable anaerobic digestion plant, with a 2,000 liter anaerobic reactor capable of generating biogas in remote areas, accelerating traditional biogas production processes. This allows the availability of a fuel gas for use in other food processing or heat generation systems.

The auxiliary energy requirements to increase are achieved by photovoltaic energy, so it is not required.

Hybrid Biogas Machine

APPLICATIONS

The thermal energy generated is subsequently used in two types of circuits: a) hot water circuits and b) hot air circuits.

Projects are currently being implemented in Central African Republic and Congo

Process

ANAEROBIC DIGESTION

Anaerobic digestion is the natural process of organic matter degradation. In this process, a multitude of symbiotic bacterial families degrade this material as part of their natural metabolism. The process can be summarized in 4 phases:

Hydrolysis

Acidogenesis

Acetogenesis

Methanogenesis

In this way, the largest and heaviest molecules are degraded in a chain until mainly methane and carbon dioxide are obtained, which are the main components of biogas.

Anaerobic digestion

ADVANTAGE

Anaerobic digestion is considered the only renewable technology that is capable of decontaminating. This is due to the capture of the methane that would be produced by the putrefaction of that matter if it were allowed to degrade naturally. It must be taken into account that one ton of methane is equivalent to 28 tons of carbon dioxide in terms of the greenhouse effect.

It is manageable energy. Once produced, biogas is stored in a very simple way, without the need for high pressures, and can be consumed over several days or weeks depending on the needs of the environment or process to which it is supplying heat.

It is an energy that can be produced in a distributed manner. The HBM, due to its small size, can feed on organic waste produced by a few animals, human waste, remains of meat processing or weighed in markets or other organic sludge. Never needing large quantities.

DATA

|

| Emission factor (kgCO2/u.) | Heat value (kWh/u.) | Cost (€/kWht) | Supply dependency |

| Biogas | -55,33 | 6,5 | 0,05 | + |

| Coal | 2,53 | 7,09 | 0,05 | +++ |

| Gasoil | 2,79 | 11,78 | 0,16 | +++ |

| Biomass | 0 | 4,41 | 0,05 | + |

DATA SHEET

| Maximum treatment capacity (t/year) | Reduction of equivalent emissions (cars) | Production of hot water at 95ºC (l/day) | Water recovery (t/year) | Organic fertilizer for crops (ha/year) |

| 40 | 70-90 | 150-200 | 20-27 | 3 |

Example of emission reduction using the waste produced by 80 sheep as input